Gantries and Cartesian

I held a pivotal position as the principal designer responsible for the development of 11 Cartesian and Gantry systems tailored specifically for the refurbishing industry.

These sophisticated systems were engineered to facilitate comprehensive testing of mobile phones, tablets, and set-top box remotes. Notably, two of these systems were crafted to enable meticulous cosmetic grading of returned phones, while an additional system was dedicated to the delicate process of buffing phone screen scratches, thereby augmenting the devices’ overall value.

My primary areas of expertise encompassed mechanical design and Programmable Logic Controller (PLC) integration. Due to intellectual property considerations, only a limited selection of images has been shared.

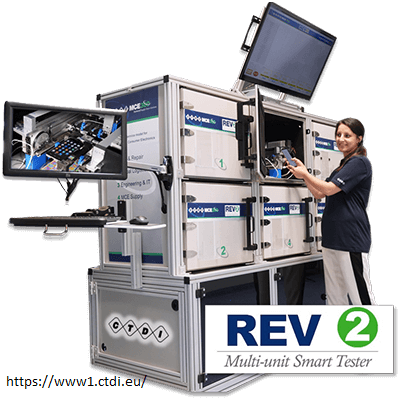

REV2 Smart Phone Robotic Tester: a 7-axis gantry system designed for RF chamber evaluations of returned phones on thousands of subtests in the refurbishing process. Successfully mass-produced in January 2018. Awarded mass produced product.

Photo credit, CTDI corporate website.

Multiple REV2 robots in RF isolation chambers> Awarded by Samsung. Massed produced product.

Photo credit, CTDI corporate website.

EVO2 is a robotic cell that is leaving in an small clean room for cosmatic grading of mobilephones. It containes a 4 axis gantry that is moving mobilephones to be chaked by an advences vision system. Jan 2019. Small Scale product.

Composit DED 3D Printing

During my tenure at Arevo, I joined the company at a critical juncture when the 3D printer MVP was being developed and the organization experienced the loss of two key designers. The primary challenge revolved around ensuring the reliability of this complex machine, which consisted of approximately 2000 types of components from 150 vendors listed in the Bill of Materials (BOM).

In my role, I took on the task of redesigning several optical subassemblies, resulting in significant improvements across multiple designs. Extensive engineering efforts were focused on enhancing power transfer mechanisms, and I also had the opportunity to design custom cyclic Instron machines and a universal fixture for our final product, Supersterata Bike.

Moreover, I am proud to have contributed to the establishment of the largest Carbon 3D printing farm, powered by AQUA printers, which stands as a testament to our dedication to pushing the boundaries of additive manufacturing technology.

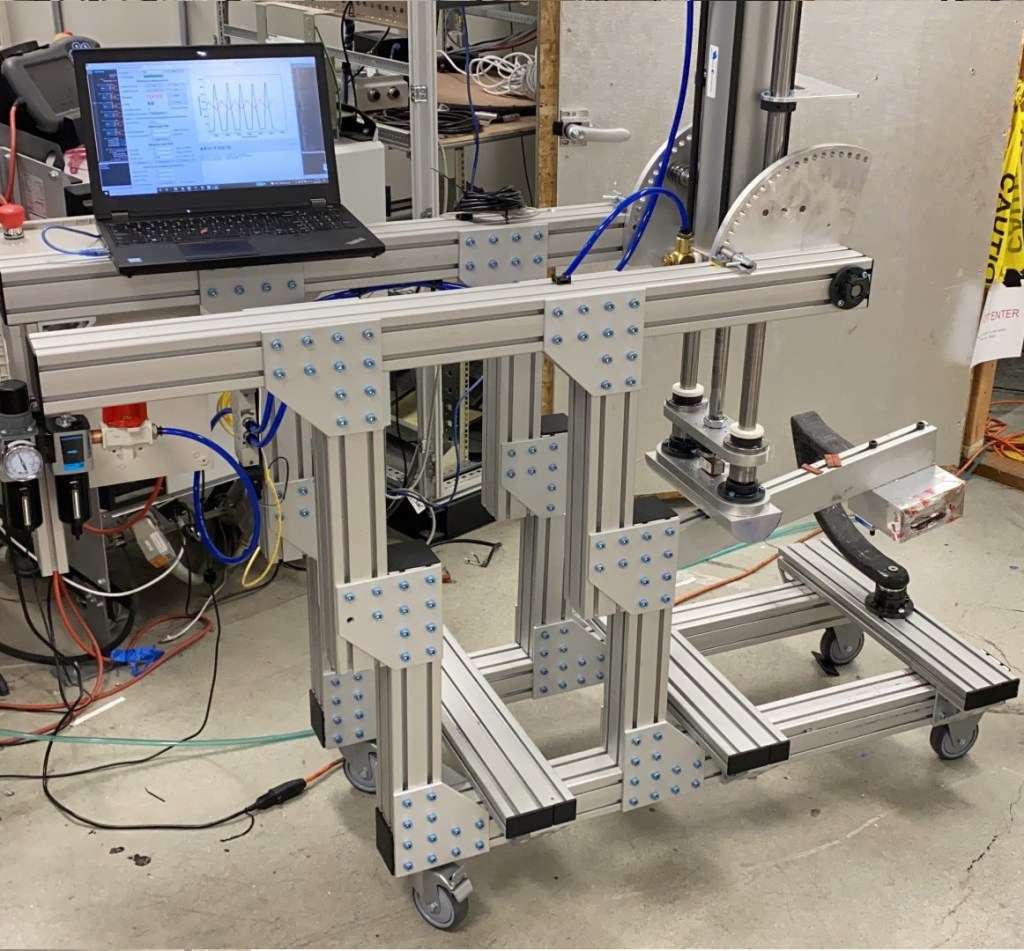

Aqua robotic cell to 3D print carbon fiber bicycles. Jul 2020. Large scale product.

Customs made Instron machine for bicycles cyclic tests. Dec 2021. Small scale product.

Universal Instron fixture to test 5 different bike components. Dec 2021.

Food Automation

I was contributing to the development of five food machines, two of which I served as the design manager for automated industrial kitchen appliances.

Two of these appliances were designed for scale up at a scale of 50,000 units, incorporating sheet metal, cast, and plastic injected parts. My primary focus was on designing efficient food hoppers optimized for large-scale manufacturing.

The remaining three machines were dedicated to ice-cream production and my role was helping a traditional owner/designer to document them in CAD 3D model.

Introducing Gen I Productization, an innovative restaurant kitchen automation machine designed for efficient plating. My responsibilities included system redesign, quality measures, reliability enhancements, condensation management, and ensuring food safety approvals. Additionally, our team is currently developing Gen II, catering to Chipotle’s online ordering with advanced dispensing subsystems, robotic features, and bowl de-nesting capabilities. Feb 2022. Mass produced product.

Reverse engineering of Ice-cream freezing machine, 2003. Large scale product.

Reverse engineering of Ice-cream packaging machine, 2003. Large scale product.

Factory Automation

I had the privilege of being a key member in designing three automated production lines. Two of these lines were dedicated to packaging and fulfillment, while the third focused on manufacturing processes.

Concept design to installation of fully automated fulfillment production line for high runner items. the line is including, box erector, line/feed/reject conveyors, spacing actuators, box ID printer, automated ejectors, custom ejectors, articulated robotic cells, high runner collaterals insert, custom made low runner collaterals insert, packing slip insert, shipping label machine, and custom dunnage machine. This line has designed based on an innovative network and control design that eliminated the control box. It is a high trough put operation with a small footprint. June 2020.

I spearheaded the system and detailed design of the deodorant end-of-line packaging solution. This comprehensive line features a QC robot, accumulation and fixturing capabilities, packaging robot, and a palletizing cell. 2022.

Photo credit, RIOS.

Initiation of the idea, feasibility study, and workflow design of a high value component production that was costly for the company. Photo credit, CTDI corporate newsletter Q2 2020.

Surgical Tables

Upon the initiation of my second business venture, I successfully delivered seven custom designed surgery tables based on four orders, catering to unique requirements. Among them, one table featured hydraulic functionality, while the remaining six were designed as electromechanical systems, showcasing versatility and adaptability to diverse surgical needs.

Veterinary surgery table, Feb 2014. MTO product.

Concept design to installation of surgery table for equines. 1400 Pounds huge horse on hydraulic surgery table, Aug 2013. MTO product.

Instruments cart of equines surgery table, Aug 2013. MTO product.

Laproscopic Surgery

In the realm of laparoscopic surgical robotics, I embarked on the design of the third-generation system following the pioneering Da Vinci and Zeus surgery robots. Despite promising initial funding prospects, progress was impeded by the impact of the global recession.

Concept design of laparoscopic surgical robot, Apr 2013.

Electromechanical laparoscopic handle, May 2013.

Lens holder for laparoscopic surgery, July 2013. MTO product.

Mass Manufactured Robotic Toys

In 2005, my partner and I started our entrepreneurial journey, establishing our own business. Our focus centered on mass manufacturing five distinct types of robotic kits, encompassing cosmetic parts, gearboxes, and electronics, all produced at scale.

Mars rover robotic kit. Mass produced product.

Two leg robotic kit. Mass produced product.

Eight leg robotic kit. Mass produced product.

Other Projects

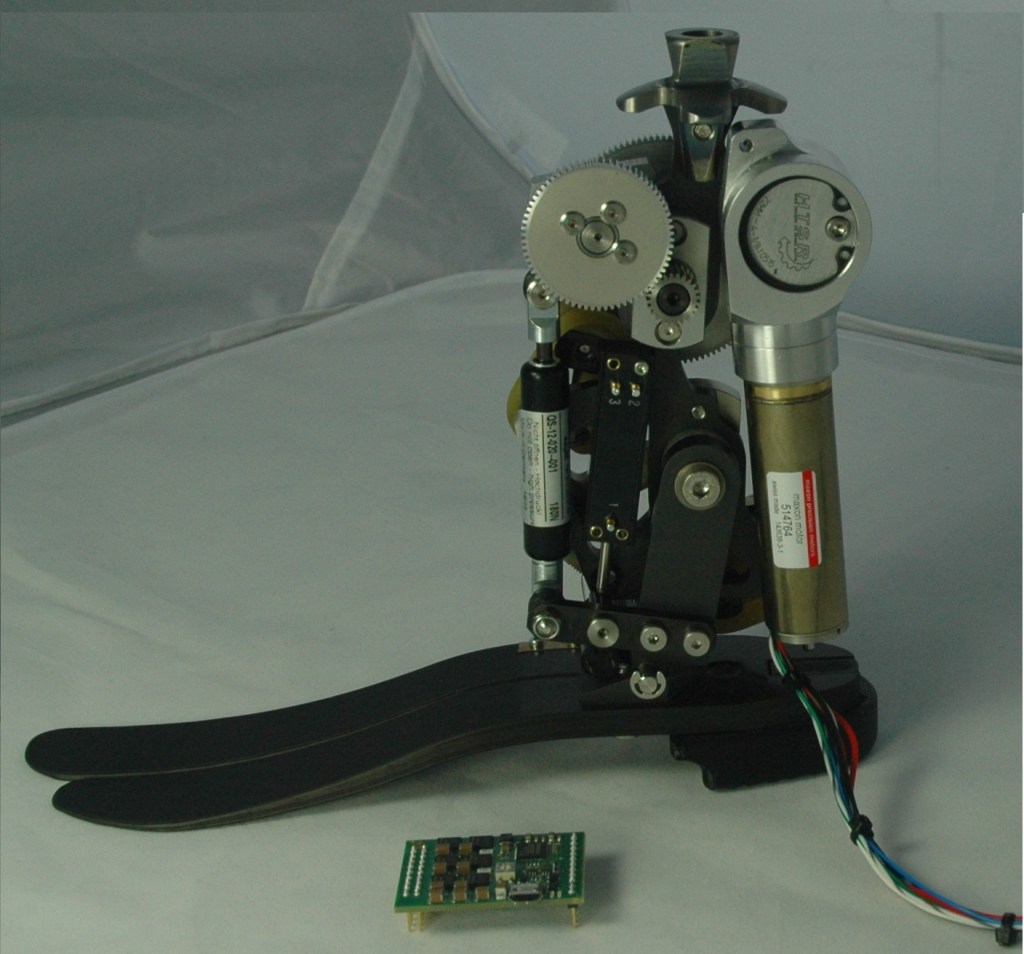

Designing the lightest powered prosthesis ankle, Jul 2015.

I authored an extensive book on robotic classification, investing four years of dedicated effort into its completion.

Tracked mobile robot with mechanical suspension, Nov 2009. Small scale product.

5 Robotic competitions. RoboCup 2003 Italy, rescue league.

5 Jewelry design projects. Luxury jewelry set with 140 round and marquise diamonds.

Pipe inspection robot, Feb 2014. MTO product.

Portable Omron PLC trainer, Apr 2012. Small scale product.

Bam earthquake robotic and sonar rescue operation, Dec 2003..

Edjucational 6 axis articulated robot, Sep 2009. Small scale product.